The Sheroz Earthworks Ideas

Table of ContentsThe 3-Minute Rule for Sheroz EarthworksWhat Does Sheroz Earthworks Do?Sheroz Earthworks Fundamentals ExplainedSheroz Earthworks Fundamentals ExplainedAbout Sheroz EarthworksAll about Sheroz Earthworks

Today, Smart Construction Remote attaches over 700 equipments on jobsites to offices, conserving countless hours previously spent by jobsite managers, surveyors and engineers travelling from workplaces to jobsites. To summarise, the initial 10 years of Komatsu's intelligent machine control have actually been marked by a decade of one-of-a-kind advancement, consistent knowing and development with consumers.

Here's to the next 10 years! Content produced in association with Komatsu.

In the rapidly evolving world of construction, accuracy and efficiency are important. 3D device control, a system that uses GPS and various other sensing units to lead equipment with identify accuracy, is revolutionising the industry - https://sitereport.netcraft.com/?url=https://sheroz.com.au. From its early days of 2D support, this technology has actually advanced substantially, making tasks that as soon as required hands-on intervention now feasible with minimal human input

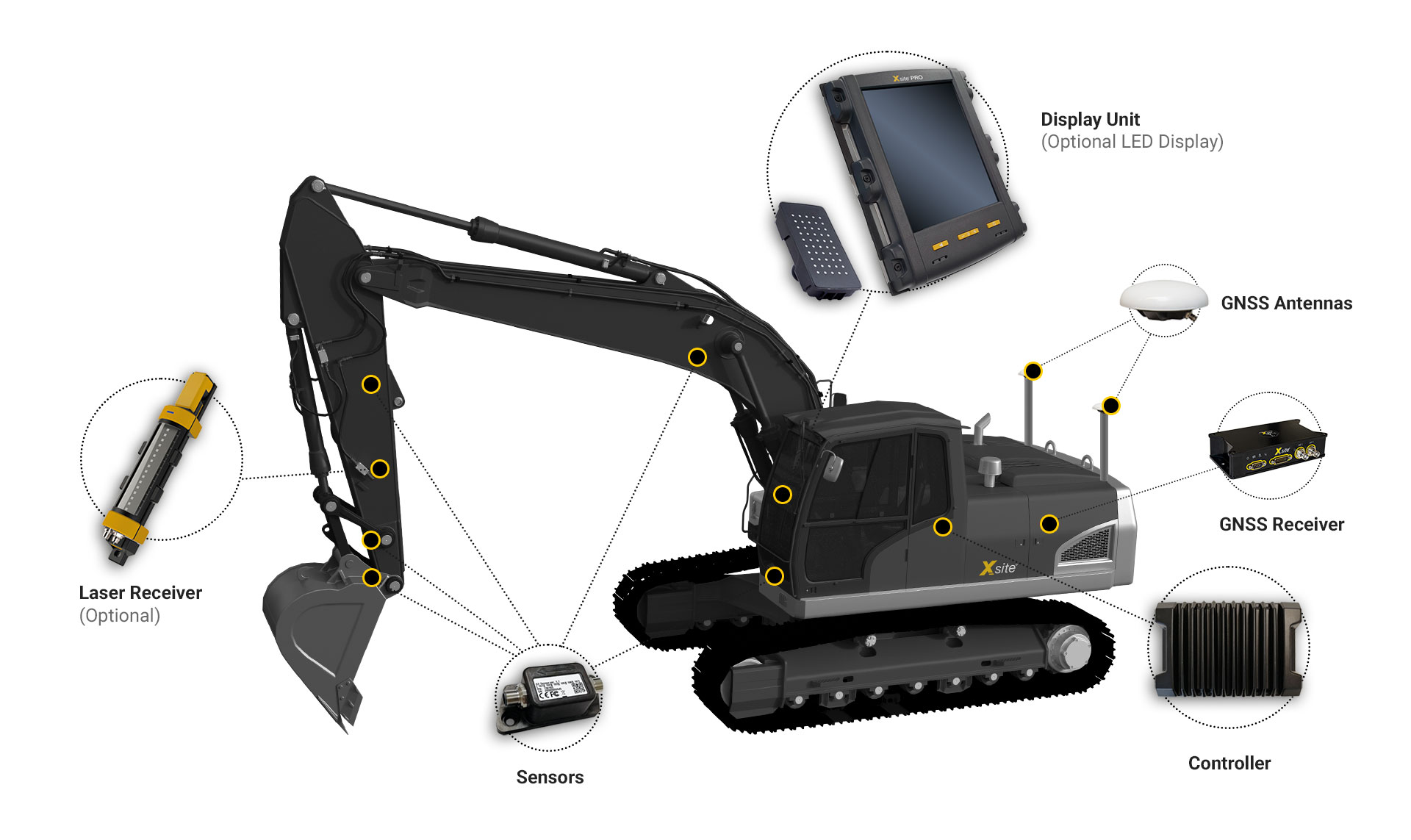

In building and construction, it ensures that every cut, fill, and grade is implemented with medical precision. Let's check out just how this game-changing technology works. At the core of any type of 3D equipment control system are GNSS receivers and antennas, capturing satellite signals to identify the maker's specific location. Onboard computer systems and control boxes process this data and communicate with the machinery.

The Greatest Guide To Sheroz Earthworks

This consists of setting up GNSS receivers, calibrating sensing units, and setting up the device control software - trimble tripod parts. The magic of 3D device control lies in its real-time information collection and processing.

User user interfaces offer real-time updates on the equipment's setting and necessary changes, guaranteeing precise control. Numerous elements influence accuracy, consisting of satellite signal high quality and sensing unit calibration. Methods like Real-Time Kinematic (RTK) placing and Exact Point Positioning (PPP) improve accuracy, making sure the highest accuracy. In construction, 3D maker control is used for earthmoving, grading, paving, and excavation, making sure tasks are completed to specific specifications.

The 15-Second Trick For Sheroz Earthworks

3D device control substantially raises performance by reducing rework and minimising material wastage, resulting in quicker and much more cost-effective job completion. The innovation makes sure every task is performed precisely as prepared, leading to regularly premium work. One of the most compelling advantages of 3D equipment control is the considerable cost financial savings it uses.

Gas consumption is optimized since machines run more properly and prevent unneeded motions. By reducing human mistake and limiting direct exposure to hazardous atmospheres, 3D machine control boosts worker safety and security and decreases crashes.

From building to mining, this modern technology guarantees jobs are performed properly and safely, minimizing costs and enhancing end results. As improvements proceed, the potential for 3D maker control to further improve performance and security expands. Welcoming this innovation is crucial for industry experts aiming to stay competitive and attain the highest possible standards in their jobs.

The smart Trick of Sheroz Earthworks That Nobody is Discussing

Discover the future of accuracy and performance currently! Likewise, look into our latest YouTube video on the FJD H36 Motor Control System to see the innovation in activity: Enjoy currently.

Over the years, we've seen operators with whole lots of experience do some fantastic things with their devices. Maybe they have an eye for adjustments that improve accuracy, or probably they understand which functions of their device to use and when to boost performance or performance - https://pagespeed.web.dev/analysis/https-sheroz-com-au/hhalrkoyid?form_factor=mobile. But with today's innovations in heavy tools technology, also competent operators can take advantage of a real-time aid to improve their day-to-day performance (topcon laser level).

This is where equipment control use this link systems factor in. Some excavators come with device control systems that direct the operator with functions to automate the digging process.

Our Sheroz Earthworks PDFs

With this included accuracy, rework is basically removed, permitting the driver to complete the project on time and relocate to the following task. For those working with hazardous or challenging jobsites, remote-controlled services open new chances. This outstanding add-on allows you to run an excavator from a distance in areas with unsafe materials (like in a potash mine) or bad ground conditions (like mud).

Maker control systems offer beneficial benefits to even more than just excavator drivers. If you have actually a truck come in with a target of 23 bunches, your operator can load their bucket and dynamically consider itoften without even being stationary.

This suggests the operator can see the specific weight of the load they will dump (topcon gps). On-board evaluating gives real-time insight into the pail's load to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building and construction EquipmentIf they unload 12 lots on the initial pass, the next container requires to consider 11 loads

See This Report about Sheroz Earthworks

Many operations utilize an on-board considering application to make sure that the lots is exact prior to they send their vehicles to the ranges, which is very important since the range weight is what's utilized for invoicing and invoicing functions. A number of makers consist of some kind of evaluating program on their loaders. Some also have functions that allow companies to monitor and control the complete lots of several trucks.